Mighty MEMS

Microtechnology brings much more to the table than

its size.

By Kathleen Kocks

|

Julie Woodford

|

Housed at Tompkins Hall within GW’s Department

of Electrical and Computer Engineering, the Institute

of MEMS and VLSI Technologies is participating in an

industrial revolution that is fundamentally changing

the electromechanical world. Breakthrough research and

developments here are inventing micro-electro-mechanical

systems (MEMS)—machines that are infinitesimally

small, extremely smart, and rapidly becoming as ubiquitous

as computer chips.

MEMS is considered an enabling technology that is creating

new products and capabilities for nearly every industrial

area. These devices can perform a seemingly infinite

number of optical, electrical, computational, thermal,

mechanical, hydraulic, or pneumatic tasks—and more.

More than 10 times smaller than a human hair’s

diameter and typically embedded onto a computer chip,

MEMS devices have the intelligence to collect and process

information, determine what to do, and send electronic

signals to effect the action.

Where can MEMS devices can be used? Virtually anyplace.

Prevalent applications today include read/write magnetic

heads for computer hard drives, inkjet printer micro-nozzles,

airbag system accelerometers, tire-pressure sensors,

micro-mirror switches, blood pressure sensors, wireless

devices, and more.

One exciting area ripe for MEMS is the biomedicine field.

In the future, MEMS-based biosensors will be small enough

to be inserted in the body to measure such factors as

blood pressure and enzyme levels.

Julie Woodford

|

|

According to a 2004 survey by the MEMS Industry Group

MIG, the major revenue streams for MEMS devices by 2007

will be micro-fluidics (27 percent), inertial sensors

(22 percent), optical MEMS (22 percent), pressure sensors

(11 percent), other sensors (10 percent), other actuators

(5 percent), and radio frequency MEMS (3 percent). It

is also estimated that about 1.6 MEMS devices are already

in service for every one person in the United States.

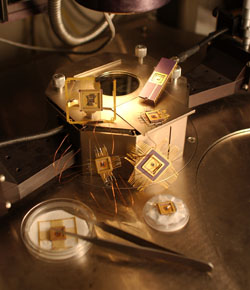

Products being developed at GW’s MEMS institute

will increase that number. One development, funded in

part by a U.S. Naval Research Laboratory grant, is a

MEMS device developed by recent GW doctoral engineering

graduate Ioana Voiculescu, DSci ’05. The device,

for which a patent is being sought, can sniff out various

chemicals that even a bloodhound’s nose would miss.

A prime application for this unique MEMS is detection

of molecular traces of explosive chemicals or nerve gases,

far better than current state-of-the-art equipment.

“We are also working on MEMS devices for mobile

phones and for HF communications; the MEMS device could

replace quartz digital crystals that are currently used

in phones and radios. We are presently testing and hoping

to get another patent for a MEMS device being developed

by two or three students; it would be used to make the

cell phone smaller or more capable of performing more

functions. I’m very excited about these products

and am hoping to get some of them commercialized,” says

Mona E. Zaghloul, the institute’s founder and professor

within GW’s Electrical and Computer Engineering

Department within the School of Engineering and Applied

Science.

“We have many other types of developments underway.

All our research is supported by grants, and we are fortunate

to have research funding from several outside sources.

Some of our supporters include the National Institute

of Standards and Technology, the NRL, and NASA. I also

have many grant proposals out right now. For one grant,

we are planning to develop MEMS power sensors to be used

on electrical power grids. These would be able to measure

power loads, determine if the system is about to fail,

and then prevent it from doing so.”

Such a device would prevent electrical blackouts similar

to the 2003 blackout across the U.S. Northeast and southeastern

Canada. The blackout affected about 50 million people,

forced nuclear power plants in New York and Ohio to close,

and nearly crippled the region’s air traffic control

system, according to Globalsecurity.org.

Established in 1997 primarily through Zaghloul’s

efforts, GW’s MEMS institute concentrates the University’s

research efforts in MEMS and in VLSI (very-large scale

integration—i.e., integrated circuits with more

than 100,000 transistors). Equally important, the institute

serves as an umbrella organization for its faculty and

graduate students. MEMS is a multidisciplinary science,

and the institute’s faculty and students come from

different departments within GW, such as chemistry and

electrical, mechanical, and biomedical engineering areas.

“We have five faculty members and about 15 graduate

students at the institute; the institute gives them a

place to do research, as well as to bond, exchange ideas,

and learn from the work of others. The institute also

houses all our published work, and our members have access

to it. Research is done at Tomkins Hall, and we have

access to labs outside the campus, such as facilities

at NIST, NASA, or NRL,” Zaghloul explains.

Zaghloul’s job as the institute’s director

is to coordinate the research and promote the institute

to others. It’s hard to imagine a better champion

for the cause. Zaghloul earned her bachelor’s degree

in electrical engineering at Egypt’s Cairo University

and her postgraduate degrees at the University of Waterloo

in Ontario, Canada. Her Waterloo degrees include master’s

degrees in electrical engineering and in computer science

and applied analysis, followed by a PhD in electrical

engineering in 1975. She was the first woman to earn

an engineering PhD at Waterloo.

In 1980, she joined GW’s Department of Electrical

Engineering and Computer Science, became a full professor

in 1984, and chaired the department from 1994 until 1998.

In all three cases, she was the first woman in these

GW positions.

Mona E. Zaghloul, professor in GW’s

Department of Electrical and Computer Engineering,

is the founder of the Institute of MEMS and VLSI

Technologies.

Julie Woodford

|

|

Zaghloul is also a Fellow in the Institute of Electrical

and Electronic Engineering, and in 1999 she received

IEEE’s Jubilee Golden Medal for outstanding contribution

to IEEE Circuits and Systems. Zaghloul has published

more than 250 technical papers, co-authored one book,

and contributed to several others. She has also supervised

more than 30 master’s theses and doctoral dissertations.

She is well known for her dedication to teaching and

is an especially strong proponent of engineering education

for women.

In 1998, Zaghloul pioneered the teaching of MEMS at

GW by introducing two graduate courses. Her expertise

in MEMS was kindled during her work as a faculty researcher

at NIST, a job that began in 1980 and continues today.

It was around 1989 or 1990 when she turned her focus

to MEMS.

“At the time, I had a very bright and creative

group of GW senior undergraduate students who also worked

at NIST and together we established the MEMS work at

NIST, while also developing some very nice sensors and

MEMS devices,” Zaghloul says. “Those students

have since been very successful in the MEMS field; some

have their own companies, one now works at Stanford University,

another at the University of California-Berkeley, another

is with Bosch, and yet another is at NASA Goddard.”

Opportunity in the MEMS field is destined to flourish.

According to the MEMS Industry Group, the MEMS commercial

market value was worth $3.9 billion in 2001 and was expected

to exceed $8 billion by 2007. Some of the more optimistic

industry analysts foresee a trillion-dollar market within

the next decade. The appeal is connected to the wide

range of MEMS applications and the ease of their manufacture.

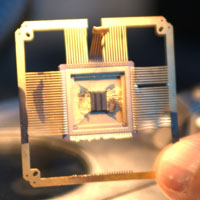

“The construction of MEMS is based upon the knowledge

we gained in making the computer microchip,” Zaghloul

explains. “That technology opened the door to build

smaller and smaller devices, at nanoscale sizes. Made

of silicon, MEMS are very tiny structures that can be

only microns in size.

|

Ioana Voiculescu, DSci ’05, has created a MEMS device that can

sniff out chemicals that even a bloodhound’s nose would miss.

Julie Woodford

|

“The technology makes it possible to build very,

very small transistors. You can not only build circuits

with MEMS, but you can also build micro-motors. Any type

of device you see around you, you can build on a very,

very small scale using MEMS technology. As you can imagine,

the potential applications for MEMS are then very diverse

and numerous.”

MEMS devices are very inexpensive to build, because

silicon is cheap and they can easily be mass-produced.

They also consume very low power, but deliver excellent

performance. MEMS experts say these small devices often

perform better and more efficiently than larger products

doing the same tasks.

“Designers have also gotten very good about designing

MEMS devices to be smart,” Zaghloul adds. “Through

circuitry, we can make them gather, analyze, and transmit

information to us. They can send a signal to other devices

and tell them what to do. They can sense their environment,

be it chemical, temperature, or otherwise. They can tell

you your blood pressure, whether your blood is diabetic,

or whether there are bacteria or chemicals present in

it.”

“As we move forward in MEMS research and development,

more and more funding agencies are now asking for even

smaller MEMS. The future is taking us toward nanoscale

sizes that are 100 times smaller than a human hair. We

are talking about very, very small machines that could

be used in many, many more applications.

“In the next age, we will find these MEMS machines

everywhere. Sometimes when I think about the future of

MEMS, I am reminded of that 1960’s movie ‘Fantastic

Voyage,’ where a small submarine and its crew were

shrunk to microscopic size, then put into a man’s

body to correct a medical problem. With nanoscale MEMS,

these devices will be able to do that kind of work in

many different kinds of ways.”

|